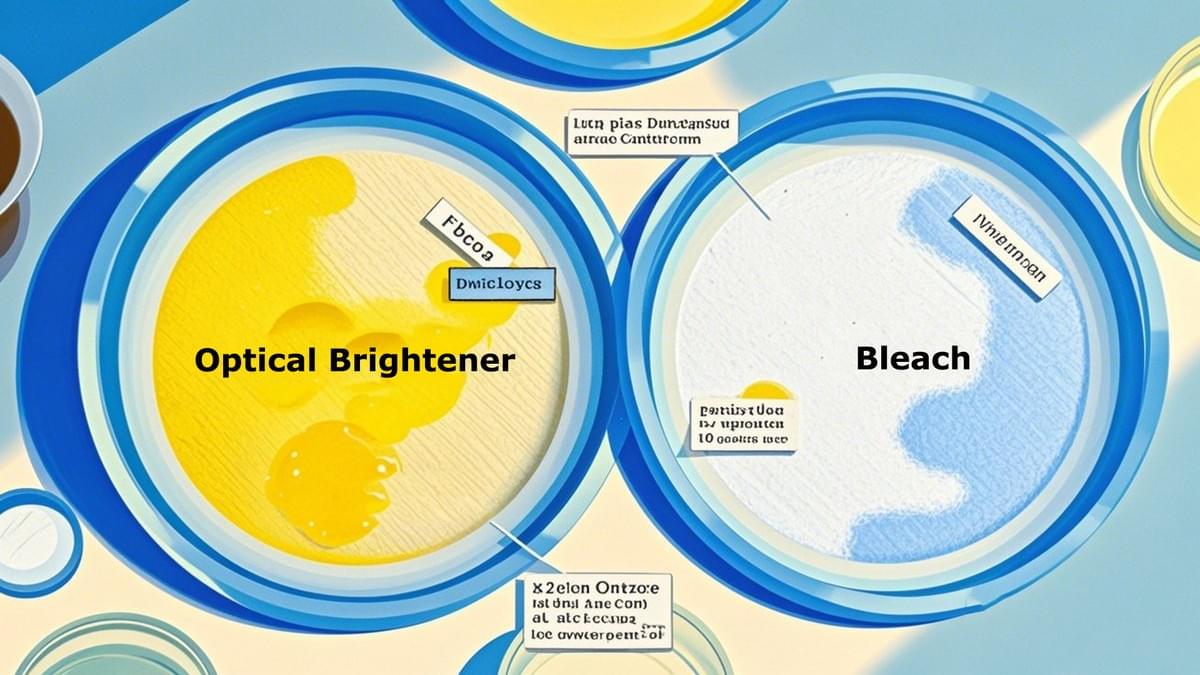

Optical Brightener and Bleach are two different chemicals, and although they both make the material look whiter, they work and work in different applications. Understanding the differences and similarities between these two substances is crucial for their effective use and safety.This article will explore in detail the definition of optical brightener, mechanism of action, application field and differences from bleach.

1.What is Optical Brightener?

1.1 Optical Brightener

Optical brighteners, or fluorescent whitening agents (FWAs), are a class of chemicals designed to enhance the brightness and whiteness of materials. These compounds work by absorbing ultraviolet (UV) light and re-emitting it as visible blue light, a phenomenon known as fluorescence. This process compensates for the natural yellowing of materials over time, making them appear whiter and more vibrant.

The molecular structure of optical brighteners is characterized by the presence of conjugated double bonds and aromatic rings, which are essential for their ability to absorb UV light. Common functional groups found in optical brighteners include:

1. Stilbene: One of the most widely used classes of optical brighteners, stilbenes have a central benzene ring with two phenyl groups attached. The conjugated system of double bonds allows for efficient absorption of UV light.

2. Coumarin: These compounds contain a benzopyrone structure, which is highly effective at absorbing UV light and emitting blue light.

3. Benzoxazole: Benzoxazoles have a benzene ring fused with an oxazole ring, providing a stable and efficient structure for fluorescence.

4. Triazine: Triazines are cyclic compounds with three nitrogen atoms in the ring, which can be modified to enhance their fluorescent properties.

The specific arrangement of these functional groups determines the wavelength of light absorbed and emitted by the optical brightener. For example, stilbene-based brighteners typically absorb UV light in the range of 340-360 nm and emit visible blue light at around 420-470 nm.

1.3 What’s the Mechanism of Action of optical brightener?

The mechanism by which optical brighteners work involves several steps:

1. Absorption: When UV light strikes the optical brightener molecule, it excites the electrons within the conjugated system, causing them to jump to a higher energy state.

2. Excited State: The excited electrons remain in this high-energy state for a brief period, typically on the order of nanoseconds.

3. Emission: As the electrons return to their ground state, they release energy in the form of visible blue light. This light is emitted at a longer wavelength than the absorbed UV light, making the material appear whiter and brighter to the human eye.

1.4 What types of Optical Brighteners are there?

There are numerous types of optical brighteners, each with its own unique properties and applications. Some of the most common types include:

1.4.1 Stilbene Derivatives:

1. Disulfonate Stilbenes: These are water-soluble and commonly used in detergents and paper products.

2. Disulfonyl Stilbenes: These are oil-soluble and often used in textile and plastic applications.

1.4.2 Coumarin Derivatives:

1. 4-Methylumbelliferone: Used in various industrial applications due to its strong fluorescence.

2. 7-Hydroxycoumarin: Effective in paper and textile whitening.

1.4.3 Benzoxazole Derivatives:

2-(2H-benzotriazol-2-yl)-4,6-bis(1-methylpropyl)phenol: Known for its excellent UV absorption and stability, it is widely used in plastics and coatings.

1.4.4 Triazine Derivatives:

4,4'-Diamino-2,2'-stilbenedisulfonic acid: Used in detergents and paper products for its strong fluorescent properties.

Each type of optical brightener has its own advantages and limitations, making them suitable for different applications. For instance, water-soluble brighteners are ideal for use in laundry detergents, while oil-soluble brighteners are better suited for textile treatments.

2. Bleach

2.1 What is Bleach?

Bleach is a versatile chemical solution used primarily for disinfection, stain removal, and whitening. The most common form of bleach is sodium hypochlorite (NaOCl), but other forms, such as hydrogen peroxide and chlorine dioxide, are also used in various applications. Understanding the chemistry of bleach is essential for grasping its effectiveness and potential risks.

2.2 What

’s the Chemical Composition of Bleach ?

Sodium hypochlorite (NaOCl) is the primary active ingredient in household bleach. It is a strong oxidizing agent that works by breaking down organic compounds through a series of chemical reactions. The chemical formula for sodium hypochlorite is NaOCl, and it is typically sold as a 5-6% aqueous solution. Other common forms of bleach include:

1. Hydrogen Peroxide (H₂O₂): A powerful oxidizer used in various applications, including hair bleaching and wound cleaning. It decomposes into water and oxygen, making it environmentally friendly.

2. Chlorine Dioxide (ClO₂): A potent disinfectant and bleaching agent used in water treatment and food processing. It is more stable and less reactive than chlorine gas.

3. Calcium Hypochlorite (Ca(OCl)₂): A solid form of bleach used in swimming pool maintenance and water treatment. It is more concentrated than sodium hypochlorite and releases chlorine upon dissolution in water.

2.3 What

’s the Mechanism of Action of bleach ?

The mechanism by which bleach works involves the release of chlorine or oxygen radicals, which break down organic compounds. Here’s a detailed breakdown of the process:

Dissociation: When sodium hypochlorite is dissolved in water, it dissociates into sodium ions (Na⁺) and hypochlorite ions (OCl⁻). The hypochlorite ion is the active bleaching agent.

NaOCl→Na++OCl−NaOCl→Na++OCl−

Formation of Hypochlorous Acid: In water, the hypochlorite ion can react with water to form hypochlorous acid (HOCl), which is a stronger oxidizing agent.

OCl−+H2O⇌HOCl+OH−OCl−+H2O⇌HOCl+OH−

Oxidation: Hypochlorous acid (HOCl) and hypochlorite ions (OCl⁻) can oxidize organic compounds, breaking down stains and microorganisms. This process involves the transfer of electrons from the organic compound to the chlorine species.

R-H+HOCl→R-Cl+H2OR-H+HOCl→R-Cl+H2O

R-H+OCl−→R-Cl+OH−R-H+OCl−→R-Cl+OH−

Decomposition: Over time, hypochlorous acid can decompose into oxygen and hydrochloric acid, releasing chlorine gas in the process.

2HOCl→2HCl+O22HOCl→2HCl+O2

This decomposition reaction is why bleach solutions lose potency over time and must be stored properly to maintain their effectiveness.

2.4 What types of Bleach are there?

Different types of bleach are used for various applications, each with its own strengths and limitations:

Sodium Hypochlorite (NaOCl):

1. Common Uses: Laundry, disinfection, and general cleaning.

2. Advantages: Readily available, inexpensive, and effective against a wide range of microorganisms.

3. Disadvantages: Can be corrosive to certain materials and may produce harmful fumes when mixed with other chemicals.

Hydrogen Peroxide (H₂O₂):

1. Common Uses: Hair bleaching, wound cleaning, and food processing.

2. Advantages: Environmentally friendly, breaks down into water and oxygen, and is less harsh on fabrics.

3. Disadvantages: Less effective at high temperatures and can be unstable in certain conditions.

Chlorine Dioxide (ClO₂):

1. Common Uses: Water treatment, food processing, and industrial cleaning.

2. Advantages: More stable and less reactive than chlorine gas, effective against a broad spectrum of microorganisms.

3. Disadvantages: Requires careful handling and storage, and can be expensive.

Calcium Hypochlorite (Ca(OCl)₂):

1. Common Uses: Swimming pool maintenance, water treatment, and industrial disinfection.

2. Advantages: Highly concentrated, long shelf life, and effective in hard water.

3. Disadvantages: Can be caustic and may require dilution before use.

Understanding the chemistry of bleach is crucial for its safe and effective use in various applications. Whether in household cleaning, industrial processes, or water treatment, the right choice of bleach can make a significant difference in achieving the desired results.

3.What’s the applications of Optical Brighteners?

Optical brighteners, or fluorescent whitening agents (FWAs), are widely used across various industries due to their ability to enhance the brightness and whiteness of materials. Their applications span from consumer goods to industrial processes, making them indispensable in many sectors.

3.1

Textile Industry

In the textile industry, optical brighteners play a crucial role in improving the appearance of fabrics. They are added to dyes and finishes to counteract the natural yellowing that occurs over time, making the fabrics appear whiter and more vibrant. The most common types of optical brighteners used in textiles are stilbene derivatives, which are effective in both synthetic and natural fibers.

1. Dyeing and Finishing: Optical brighteners are often incorporated into dye formulations to enhance the color intensity and brightness of the fabric. They can be applied during the dyeing process or as a post-treatment step.

2. Washing and Care: Many laundry detergents contain optical brighteners to keep clothes looking fresh and clean. These brighteners adhere to the fabric and continue to fluoresce even after multiple washes, maintaining the whiteness and brightness of the garments.

3.2

Paper Industry

The paper industry is another major user of optical brighteners. These chemicals are used to improve the visual appeal of paper products, making them appear whiter and more appealing to consumers. Optical brighteners are particularly useful in the production of high-quality paper, such as office paper, magazine paper, and packaging materials.

1. Papermaking: Optical brighteners are added to the pulp during the papermaking process to enhance the whiteness of the final product. They are especially effective in counteracting the yellowing caused by lignin, a natural component of wood pulp.

2. Coatings and Finishes: In addition to the paper itself, optical brighteners can be used in coatings and finishes applied to the surface of the paper. This not only improves the whiteness but also enhances the printability and overall quality of the paper.

3.3 Plastics Industry

The plastics industry uses optical brighteners to improve the appearance of plastic products. These chemicals can be added to the raw materials during the manufacturing process to create a brighter, more attractive final product. Optical brighteners are particularly useful in applications where aesthetics are important, such as in consumer goods, automotive parts, and packaging.

1. Raw Material Additives: Optical brighteners are often added to the polymer matrix during the extrusion or molding process. This ensures that the brightening effect is uniform throughout the product.

2. Surface Treatments: In some cases, optical brighteners are applied as a surface treatment to existing plastic products. This can be done through spraying, dipping, or coating processes, depending on the specific application.

3.4

Detergent Industry

In the detergent industry, optical brighteners are a key component of many laundry detergents and fabric softeners. They help to keep clothes looking fresh and clean by adhering to the fabric and continuing to fluoresce even after multiple washes.

1. Laundry Detergents: Many liquid and powder detergents contain optical brighteners to enhance the whiteness and brightness of clothes. These brighteners are designed to be compatible with a wide range of fabric types and washing conditions.

2. Fabric Softeners: Fabric softeners often include optical brighteners to provide an additional boost to the appearance of fabrics. This not only improves the feel of the fabric but also enhances its visual appeal.

3.5 Other Industries

Optical brighteners are also used in various other industries, including:

1. Cosmetics and Personal Care: In cosmetics, optical brighteners can be used to enhance the appearance of skin and hair. They are often found in shampoos, conditioners, and skincare products.

2. Paints and Coatings: In the paints and coatings industry, optical brighteners are used to improve the color and appearance of painted surfaces. They can be added to both water-based and solvent-based paints.

3. Printing Inks: Optical brighteners are used in printing inks to enhance the brightness and clarity of printed images, making them more visually appealing.

4.What’s the environmental impact of Optical Brighteners and Bleach ?

The widespread use of optical brighteners and bleach has raised concerns about their environmental impact. Both chemicals can have significant effects on ecosystems and water quality, and understanding these impacts is crucial for promoting sustainable practices.

4.1 Optical Brighteners

4.1.1 Persistence in the Environment:

1. Biodegradability: Many optical brighteners are designed to be stable and resistant to degradation, which can lead to their persistence in the environment. Some studies have shown that certain types of optical brighteners can persist in water bodies for extended periods, potentially accumulating in sediments and aquatic organisms.

2. Bioaccumulation: The persistence of optical brighteners can result in bioaccumulation in the food chain. Aquatic organisms, such as fish and invertebrates, can absorb these chemicals, leading to potential health effects and ecological imbalances.

4.1.2 Toxicity:

1. Aquatic Life: Optical brighteners can be toxic to aquatic organisms at certain concentrations. Studies have shown that exposure to high levels of optical brighteners can affect the growth, reproduction, and survival of fish and other aquatic life.

2. Human Health: While the direct toxicity of optical brighteners to humans is generally low, there are concerns about their potential long-term effects. Some research suggests that prolonged exposure to optical brighteners may cause skin irritation and allergic reactions in sensitive individuals.

4.1.3 Eutrophication:

Nutrient Release: The breakdown of optical brighteners in water can release nutrients, contributing to eutrophication. Eutrophication is a process where excessive nutrients in water bodies lead to algal blooms, which can deplete oxygen levels and harm aquatic ecosystems.

4.2 Bleach

4.2.1 Toxicity:

1. Aquatic Life: Sodium hypochlorite, the most common form of bleach, is highly toxic to aquatic organisms. Even at low concentrations, bleach can be lethal to fish, invertebrates, and other aquatic life. The release of bleach into water bodies can have severe ecological consequences.

2. Human Health: Exposure to bleach can cause respiratory issues, skin irritation, and eye damage. Inhaling bleach fumes, especially in enclosed spaces, can be particularly harmful. Accidental ingestion of bleach can lead to serious health problems, including burns to the mouth and throat, and gastrointestinal issues.

4.2.2 Chlorine Compounds:

1. Formation of Disinfection Byproducts (DBPs): When bleach is used in water treatment, it can react with organic matter to form disinfection byproducts (DBPs), such as trihalomethanes (THMs) and haloacetic acids (HAAs). These compounds are known to be carcinogenic and can pose long-term health risks to humans.

2. Environmental Persistence: Chlorine compounds can persist in the environment and accumulate in soil and water. This can lead to the formation of chlorinated organic compounds, which are difficult to degrade and can have long-lasting ecological impacts.

4.2.3 Impact on Microbial Communities:

Disruption of Ecosystems: Bleach's strong disinfectant properties can disrupt microbial communities in water bodies and soil. This disruption can affect nutrient cycling, decomposition processes, and the overall health of ecosystems.

5.Mitigation Strategies: How to minimize the environmental impact of optical brighteners and bleach?

To minimize the environmental impact of optical brighteners and bleach, several strategies can be employed:

1. Consumer Awareness: Educating consumers about the environmental impact of these chemicals can encourage more responsible usage. Simple changes, such as using eco-friendly detergents and reducing the frequency of bleach use, can make a significant difference.

2. Industrial Practices: Industries can adopt more sustainable practices, such as using biodegradable optical brighteners and implementing wastewater treatment systems to remove these chemicals before discharge.

5.2 Alternative Products:

1. Eco-Friendly Alternatives: Developing and promoting eco-friendly alternatives to optical brighteners and bleach can reduce their environmental impact. For example, using plant-based brighteners and natural disinfectants like vinegar and baking soda can be effective and safer options.

2. Biodegradable Formulations: Research into biodegradable optical brighteners and bleach alternatives is ongoing. These formulations can break down more easily in the environment, reducing the risk of long-term ecological damage.

5.3 Regulatory Measures:

1. Environmental Regulations: Governments can implement regulations to control the use and disposal of optical brighteners and bleach. Setting limits on the concentration of these chemicals in products and requiring proper disposal methods can help protect the environment.

2. Monitoring and Enforcement: Regular monitoring of water bodies and enforcement of environmental standards can ensure compliance and reduce pollution.

By understanding the environmental impact of optical brighteners and bleach and implementing effective mitigation strategies, we can promote more sustainable practices and protect our ecosystems.

6.Safety Considerations: How to use Optical Brighteners and Bleach safely ?

Using optical brighteners and bleach safely is crucial to prevent accidents and health hazards. Both chemicals have specific safety guidelines and precautions that should be followed to ensure their safe handling and storage.

6.1

Optical Brighteners

6.1.1 Skin and Eye Contact:

1. Irritation: Optical brighteners can cause skin irritation and allergic reactions in sensitive individuals. Prolonged contact with the skin should be avoided.

2. Eye Protection: If optical brighteners come into contact with the eyes, they can cause irritation and discomfort. It is important to wear appropriate eye protection, such as safety goggles, when handling these chemicals.

6.1.2 Inhalation:

Vapor Inhalation: Some optical brighteners can release vapors that may be harmful if inhaled. Ensure adequate ventilation in areas where optical brighteners are used, and consider wearing a respirator if necessary.

6.1.3 Storage:

1. Temperature and Light Sensitivity: Optical brighteners can degrade when exposed to high temperatures or direct sunlight. Store them in a cool, dry place away from heat sources and light.

2. Compatibility: Store optical brighteners separately from incompatible materials, such as acids and strong oxidizers, to prevent reactions.

6.1.4 Disposal:

Proper Disposal: Follow local regulations for the disposal of optical brighteners. Do not pour them down drains or into water bodies. Dispose of them according to the manufacturer's instructions or through approved waste management facilities.

6.2

Bleach

6.2.1 Skin and Eye Contact:

1. Burns and Irritation: Bleach is a strong irritant and can cause burns and severe irritation to the skin and eyes. Always wear gloves and protective eyewear when handling bleach.

2. First Aid: If bleach comes into contact with the skin, rinse the affected area thoroughly with water for at least 15 minutes. If it gets into the eyes, flush the eyes with water for at least 15 minutes and seek medical attention immediately.

1. Fumes: Inhaling bleach fumes can cause respiratory issues, including coughing, shortness of breath, and irritation of the nose and throat. Use bleach in well-ventilated areas and avoid mixing it with other chemicals, especially ammonia, as this can produce toxic gases.

2. Respiratory Protection: Consider wearing a respirator in enclosed spaces or when using large quantities of bleach.

6.2.3 Ingestion:

1. Toxicity: Accidental ingestion of bleach can be extremely dangerous, causing burns to the mouth, throat, and stomach. If ingested, do not induce vomiting; instead, drink plenty of water and seek immediate medical attention.

6.2.4 Storage:

1. Labeling: Clearly label all containers of bleach to avoid confusion. Store bleach in a secure, child-proof location to prevent accidental ingestion.

2. Compatibility: Store bleach separately from acids, ammonia, and other reactive chemicals to prevent dangerous reactions.

6.2.5 Disposal:

1. Proper Disposal: Follow local regulations for the disposal of bleach. Dilute small amounts of bleach with water and pour it down the drain with running water. For larger quantities, follow the manufacturer's instructions or consult with local waste management authorities.

7. Conclusion

Optical brighteners and bleach are both essential chemicals with a wide range of applications, from enhancing the appearance of materials to ensuring hygiene and cleanliness. While they share the goal of improving the visual and functional qualities of products, they operate through fundamentally different mechanisms. Optical brighteners achieve their effects through fluorescence, absorbing UV light and re-emitting it as visible blue light, while bleach works through oxidation, breaking down organic compounds.

Understanding the chemistry, applications, environmental impact, and safety considerations of these chemicals is crucial for their effective and responsible use. By following best practices and adopting sustainable alternatives, we can minimize their environmental footprint and ensure the safety of users. Whether in the textile, paper, plastics, or detergent industries, the judicious use of optical brighteners and bleach can contribute to a cleaner, brighter, and more sustainable world.